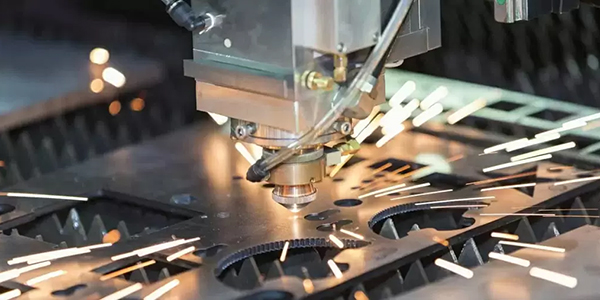

High Speed Laser Cutting

Singochwepheshe bokusika i-laser futhi sicubungula ukumelana nokugqokwa, izikhali kanye nezinto zokwakha ze-High Strength Low Alloy. Amabanga afana ne-Hardox (amageji amaningi agcinwe esitokweni sangaphambili), i-Weldox, i-Abrazo, i-Armox, ne-Invar & Abro wonke angacutshungulwa aze afike ku-25mm ubukhulu.

Siphethe isitoko esilinganiselwe salezi zinto zokusebenza ukuze senze ushintsho olusheshayo. Siphatha inqwaba yesitoko se-Domex & Hardox futhi sicubungula lezi zinto njalo.

Sicela ushayele ukuze uthole imininingwane eyengeziwe kanye nokutholakala kwesitoko samanje.

I-Waterjet Cutting

Uhlelo lwethu lokusika lwe-Waterjet lusebenzisa amanzi ku-50,000 psi kanye negarnet ehubhukayo ukusika noma iyiphi into, kuhlanganise ne-titanium! Amaphampu okuqinisa ahlinzeka ngamandla amahhashi angu-150, avumela ukusebenza okungcono nakakhulu ezintweni eziwugqinsi. Ezinye zezinzuzo ze-waterjet zifaka: Ikhono lokusika ijamo eliphakeme. Ukusika izinto ezinye izindlela azikwazi, njengerabha yegwebu, ithayela le-ceramic, imabula, nengilazi. Iphatha inhlobonhlobo yezinto kalula. ± 0.005" ukunemba kokuma. Iqeda izimbobo zokungena ngaphambili. Isebenza kancane kunezinye izindlela. Ingasika izinto eziwugqinsi kakhulu (Sisike ithusi eliwugqinsi elingu-8!).

Irutha eqondile

Ukusika kuhlangana kufika kumayintshi angu-3,150 ngomzuzu.

• Indlela eshesha kakhulu yokucubungula i-aluminium, i-SS, i-CS ne-alloy Steel.

72" x 144" ithebula elinemvilophu yomsebenzi engu-84" x 140" kanye no-15" wohambo lwe-z-axis.

• Ingakwazi umshini izinto eziwugqinsi nezingxenye kufika ku-6' x 12'.

Isistimu yokupholisa izikhukhula yezinto ezisebenza kanzima emshinini

• Ivumela isivinini esiphezulu namazinga okuphakelayo, inyusa impilo yamathuluzi, yehlise ingxenye yezindleko.

• Ukwazi ukwenza insimbi engagqwali kanye ne-titanium.

Amandla angama-20-horsepower, i-HSK 63A yokuphotha epholise uketshezi enokupholisa ngethuluzi nokushintsha kwamathuluzi ashukumisayo okudidiyelwe.

• Isistimu yokubamba yamathuluzi ethuthukisiwe.

• Ukupholisa ngethuluzi kusho imisebenzi yokumba ejulile esheshayo.

• Iziteshi zamathuluzi eziyi-12 zivumela cishe noma yimuphi umsebenzi ukuba wenziwe ngomshini ngaphandle kokulungiswa kabusha.

40-amahhashi high-flow vacuum futha futha.

• I-vacuum eyengeziwe isiza ukubamba amapuleti awugqinsi noma izingxenye eziningi ezincane endaweni yawo.

± 0.0004" (0.01mm) ukuphindaphinda okukodwa kanye nokujikeleza okungu-± .0025".

• Izingxenye eziqediwe ezinembe kakhulu.

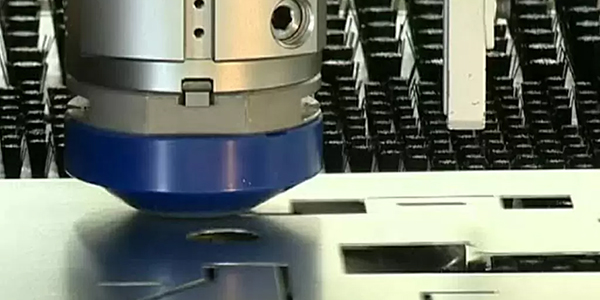

Incazelo Ephakeme Ye-Plasma Cutting

Ukusika i-Plasma sekuyisikhathi eside kubonwa njengendlela engabizi kakhulu esikhundleni se-oxy-fuel kanye nephrofayili ye-laser lapho i-cut angle yayingeyona inkinga. Intuthuko yakamuva yenqubo ye-plasma enembayo ephezulu/yencazelo ephezulu ithuthukise kakhulu ikhwalithi namandla okusika i-plasma, okwenza kube inketho eguquguqukayo nenembile kunangaphambili.

Ukufaneleka Kohlelo

Ukusika kwe-Plasma kulungele izinto ezahlukahlukene ikakhulukazi izinsimbi ezithambile nezinsimbi ezingenasici ezikhiqiza isiphetho esihle kakhulu sonqenqema.

Ukuthuthukiswa kwezinhlelo zokulawula manje kusho ukuthi ukusebenza kahle kokusika kwezinhlobonhlobo zezinto nobukhulu obusuka ku-1mm ukuya ku-50mm ngensimbi ethambile (kuncike emandleni eyunithi ye-plasma) kungafinyelelwa.

Amapharamitha ahlotshaniswa nokusika izinto eziningi ezihlukahlukene kanye nobukhulu obufana nesivinini sokusika, izinhlobo zegesi nezingcindezi zegesi manje zingalawulwa ngokuzenzakalelayo ngemishini, kuqinisekiswe ikhwalithi yokusika ephezulu ngokungaguquki. Abasebenzisi manje banenye indlela engabizi ngempela kwezinye izinqubo zokusika.

I-CNC Punches

I-CNC Punching sheet metal isebenza ngamathuluzi we-CNC Punch kanye ne-CNC Punch Presses. I-Computer numberally controlled (CNC) punching iyinqubo yokukhiqiza eyenziwa yi-CNC punch press. Le mishini ingaba idizayini eyodwa yekhanda nethuluzi (Trumpf) noma idizayini ye-turret enamathuluzi amaningi. Umshini uhlelelwe ukuthi uhambise ishidi lensimbi liqonde ku-x kanye no-y ukuze ubeke kahle ishidi ngaphansi kwenqama yokubhoboza yomshini elungele ukubhoboza imbobo.

Ibanga lokucubungula lemishini eminingi yokunyathelisa ye-punch ye-CNC lingu-0.5mm kuya ku-6.0mm ohlotsheni lwezinto ezihlanganisa insimbi, i-zintec, i-galv, insimbi engagqwali ne-aluminium.Ukukhethwa kwembobo ebhotshoziwe kungaba lula njengendingilizi noma unxande udlulele emimoyeni ekhethekile ukuze ivumelane nomklamo othile osikiwe. Ngokusebenzisa inhlanganisela yamahithi okukodwa kanye namajiyometri agqagqene, amajamo wengxenye yensimbi yeshidi eliyinkimbinkimbi angakhiqizwa. Umshini ungase futhi ushaye amafomu e-3D afana nama-dimples, i-taptite® screw thread plunges, nama-knockout kagesi njll nhlangothi zombili zeshidi, okuvame ukusetshenziswa ekwakhiweni kwesivalo seshidi lensimbi. Eminye imishini yesimanje ingase ibe nekhono lokuthepha izintambo, ukugoqa amathebhu amancane, ukubhoboza imiphetho egundayo ngaphandle kwanoma yimaphi amamaki ofakazi bethuluzi okwenza umshini ukhiqize kakhulu phakathi nesikhathi somjikelezo wengxenye. Umyalelo wokushayela umshini ukuze udale ingxenye yejometri efiselekayo waziwa ngokuthi wuhlelo lwe-CNC.