Ukwakheka Kwamakhemikhali

| Ibanga | C≤ | Si≤ | Mn≤ | P≤ | S≤ | Ni | Cr |

| 201 | 0.15 | 1 | 5.50-7.50 | 0.5 | 0.03 | 3.50-5.50 | 16.00-18.00 |

| 202 | 0.15 | 1 | 7.50-10.00 | 0.5 | 0.03 | 4.00-6.00 | 17.00-19.00 |

| 304 | 0.08 | 1 | 2 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

| 304L | 0.03 | 1 | 2 | 0.045 | 0.03 | 8.00-12.00 | 18.00-20.00 |

| 309 | 0.2 | 1 | 2 | 0.04 | 0.03 | 12.00-15.00 | 22.00-24.00 |

| 309S | 0.08 | 1 | 2 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

| 310 | 0.25 | 1 | 2 | 0.04 | 0.03 | 19.00-22.00 | 24.00-26.00 |

| 310S | 0.08 | 1 | 2 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

| 316 | 0.08 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

| 316L | 0.03 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

| 316Ti | 0.08 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

| 410 | 0.15 | 1 | 1 | 0.04 | 0.03 | 0.6 | 11.50-13.50 |

| 430 | 0.12 | 0.12 | 1 | 0.04 | 0.03 | 0.6 | 16.00-18.00 |

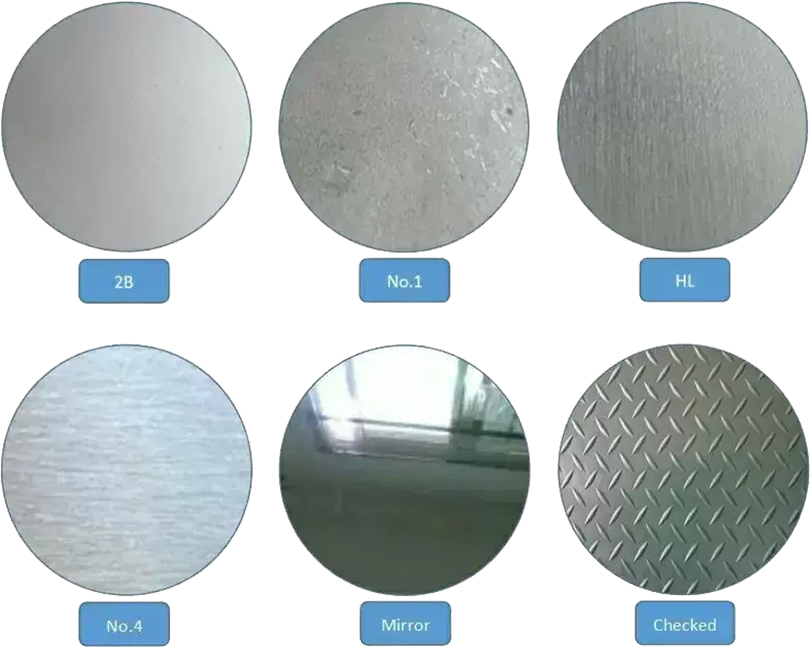

I-Surface Finish Yekhoyili Yensimbi Engagqwali

| I-Surface Qeda | Incazelo | Isicelo |

| No.1 | Ingaphezulu liqedwe ukwelashwa kokushisa kanye nokukhetha noma izinqubo ezihambisana lapho ngemva kokugoqa okushisayo. | Ithangi lamakhemikhali, ipayipi |

| 2B | Lezo ziqedwa, ngemva kokuginqika okubandayo, ngokuphathwa ukushisa, ukucotshwa noma okunye ukwelashwa okufanayo futhi ekugcineni ngokuginqika okubandayo ukuze kunikezwe ukukhanya okufanele. | Imishini yezokwelapha, Imboni Yokudla, Izinto zokwakha, Izitsha zasekhishini. |

| No.4 | Lawo aqedelwa ngokupholishwa ngama-abrasives No.150 kuya ku-No.180 acaciswe ku-JIS R6001. | Izitsha zasekhishini, Impahla kagesi, Ukwakhiwa kwebhilidi. |

| Izinwele | Lezo eziqediwe zokupholishwa ukuze zinikeze imivimbo yokupholisha eqhubekayo ngokusebenzisa i-abrasive yosayizi ofanele wokusanhlamvu. | Ukwakhiwa Kwezakhiwo. |

| I-BA/8K Mirror | Lezo zicutshungulwe ngokwelashwa kokushisa okukhanyayo ngemuva kokugoqa okubandayo. | Izitsha zasekhishini, Impahla kagesi, Building const |

Ulwazi Lwensimbi Engagqwali

●304 Insimbi Engagqwali

I-304 insimbi engagqwali iyinto eguquguqukayo kakhulu evame ukusetshenziswa ekwenzeni okokusebenza kanye nezingxenye ezidinga izakhiwo ezinhle kakhulu zizonke, okubandakanya ukumelana nokugqwala kanye nokwakheka. Ukuqinisekisa ukumelana kwayo nokugqwala, insimbi engagqwali kufanele okungenani ibe ne-chromium engu-18% kanye ne-nickel engu-8%.

Izinga le

Ukwakhiwa kwensimbi engu-304 kudlala indima ebalulekile ekunqumeni ukumelana nokugqwala kwayo kanye nenani. Nakuba i-nickel (Ni) ne-chromium (Cr) kuyizinto eziyinhloko, ezinye izingxenye zingase zibandakanyeke. Izinga lomkhiqizo licacisa izidingo ezithile zensimbi engu-304. Ngokuvamile kuqondwa embonini ukuthi uma okuqukethwe kwe-Ni kudlula i-8% futhi okuqukethwe kwe-Cr kudlula i-18%, kungahlukaniswa njengensimbi engu-304. Yingakho ngokuvamile ibizwa ngokuthi 18/8 insimbi engagqwali. Kumele kuqashelwe ukuthi kunemithethonqubo ecacile emazingeni omkhiqizo afanele we-304 steel, futhi le mithetho ingase ihluke ngokuvumelana nokuma kanye nesimo sensimbi engagqwali.